Wayland Additive Will Demonstrate Benefits Of Calibur3 Metal Additive Manufacturing At Amads

Wayland Additive, an OEM of next generation eBeam metal additive manufacturing (AM) systems, will be highly visible at the upcoming AMADS (AM for Aerospace, Defence & Space) event, taking place in Bristol 27th and 28th February. Aerospace, defence and space applications of metal AM are amongst the most advanced in the sector, but progress can be limited by the limitations of the technologies available – especially with more exotic materials. This is where Calibur3 comes in, featuring Wayland’s NeuBeam process.

At AMADS, members of the Wayland Additive team will engage with attendees to highlight the ground-breaking capabilities of Calibur3 and demonstrate the stability and versatility of NeuBeam for processing a much wider range of industrial materials for production applications that are much wider in scope than existing AM processes allow.

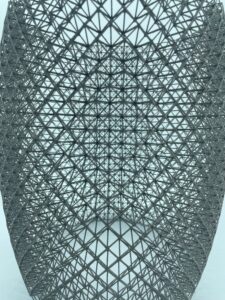

Calibur3 introduces a genuine paradigm shift in eBeam powder bed fusion (PBF) technology. It represents a significant advancement compared with existing PBF systems, overcoming the inherent compromises associated with laser or traditional eBeam processes for metal materials. Design engineers and manufacturers of difficult applications can now revisit challenging or previously impossible projects with a more open approach.

Peter Hansford, CRO at Wayland comments, “Metal AM, in general, has come a long way and has made inroads for some production applications. Calibur3 has the potential to take production applications to the next level in a number of ways. At AMADS, our team members will be available to discuss new applications and new materials enabled by the capabilities of NeuBeam. We invite AMADS attendees to learn more about our hot part process, which eliminates residual thermal stresses, simplifies powder removal, and reduces post-processing requirements as well as the open approach that allows us to test and prove new material parameters in a matter of weeks.”

The NeuBeam process effectively neutralizes charge accumulation generated by the electron beam, providing greater flexibility compared to laser PBF and surpassing the stability issues of traditional eBeam PBF. This unique attribute enables tailored metallurgical requirements to match specific application needs, expanding the range of metal materials that can be utilized in the process. With NeuBeam, Wayland Additive not only enhances process development but also eliminates residual stresses, resulting in stress-free, crack-free parts, reduced energy consumption, and improved powder flow post-build.

Hansford continues, “Since commercialising our technology two years ago, Wayland is now shipping machines all over the world across a variety of industry sectors, including aerospace, to exploit the potential of our NeuBeam AM process.”

#modernplasticsindia #indianplasticmagazine #modernplasticsaward #plasticnews #modernplasticsgermany #ginujoseph #modernplastic #plasticindia #plasticrecycling #sustainability #modernplasticsglobalnetwork #modernglobalnetwork #modernplasticsaward2023 #plasticmagazine #PlasticIndustry #modernplasticsmiddleeast #indianmagazine #innovations #modernplasticsamerica #modernplasticsbangladesh #modernplasticsasia #modernplasticsitaly