Farrel Pomini’s Breakthrough Enhances Rigid PVC Processing Efficiency

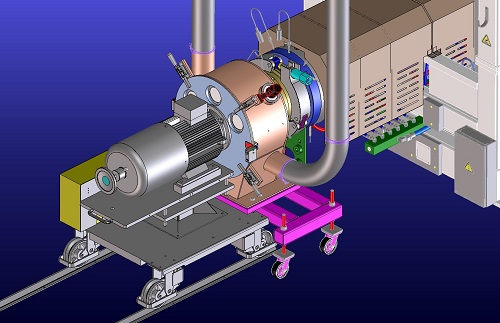

The FCM, Farrel Continuous Mixer and newly designed Dry Face Pelletizer combine to eliminate traditional finishing steps

Farrele Domini, the leader in the field of continuous connection systems for polymer processing, offers an economically effective and safe method for processing a virgin or processed hard PVC, which eliminates traditional references using its recently designed dry person sediment (DFP).

The process begins with the strengthening of the hard PVC with a continuous Farrel mixer (FCM) to a single circuit extruder with a hot power supply (compact processor). The PVC is cooled when it goes through the extruder and moves to the patented DFP, which minimizes the pressure and the increase in the potential temperature with an effective cut of granules. After cultivation, the air transfer system completes the cooling process with pants and dust classification and fine removal of particles.

This cost-effective concept eliminates the need for finishing the rigid PVC with a two-roll mill, water bath and dicer – allowing for a smaller capital investment and equipment footprint as well as expedited return on investment and enhanced safety. The compact DFP is easy to operate and can be fully integrated into the user-friendly FARREL POMINI SYNERGY Control System. The entire line can be completely automated with minimal operator involvement.

Meanwhile, the standard 6 L/D rotor of the energy efficient FCM provides a short residence time and low heat history, especially important for processing temperature-sensitive PVC. Continuous mixing technology also features:

- Adjustable mixing intensity achieved by changing rotor speed and orifice position.

- Excellent temperature control throughout the mixing chamber, rotors and extruder barrel.

https://www.farrel-pomini.com/

#farrel-pomini #Modernplasticsindia #Pasticsnews #ModernPlasticsIndiaMagazine

#Modernplasticsmiddleeast