Even if the Corona pandemic crisis has side-lined the issue a little in recent months, conducting business in a climate-conscious and sustainable manner remains as important as ever and is high on the agenda of companies, organizations and end consumers.

As a specialist for the development and production of polymere specific color, additive- and multifunctional masterbatches another step in the right direction already being pursued by ROWA Masterbatch is the development of sustainable products.

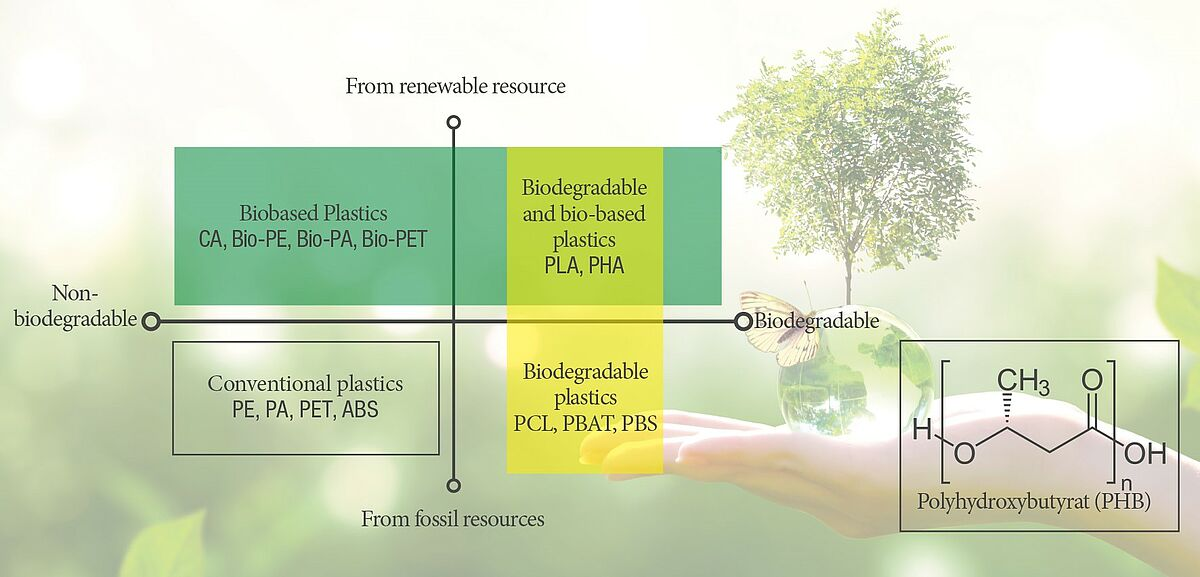

These products, referred to as bioplastics, are differentiated between bio-based and biodegradable: Bio-based plastics are produced from renewable raw materials, such as starch or sugar. The term biodegradable refers to plastics that can be decomposed by microorganisms. This results in the following three groups of bioplastics:

> bio-based, non-biodegradable plastics: Bio-PE, Bio-PA, Bio-PET, CA

> bio-based, biodegradable plastics: PLA, PHA

biodegradable plastics of fossil origin: PCL, PBAT, PBS

Until now bioplastics have been used mainly for food packagings, toys and some technical applications – although in relative terms they are still very rare. Dorit Krienke, Head of Development at ROWA Masterbatch, is certain that “The topic will gain momentum in the coming years. The demand for bioplastics will increase significantly. At ROWA Masterbatch we are well prepared and are the perfect partner when it comes to processing these kind of products”.

ROWA Masterbatch works polymer-specific and can therefore process virtually all possible materials – including, of course, biopolymers. “We develop custom color and additive concentrates for our customers and are open for projects in all future-oriented fields”, said Mrs. Krienke.