Tribo-Chemical Film as Superlubricity for Polymers

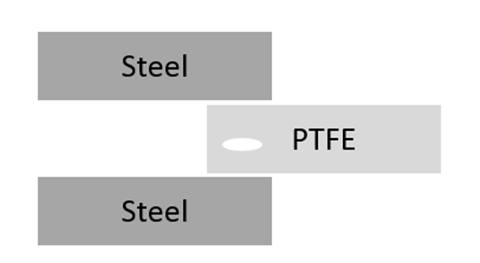

When two crystalline surfaces slide over each other in dry medium with negligible friction known as super lubricity. Basically the with two low surface energy of polymers moderately induce with pouring liquid of highly thin layer may obtain the superlubricity property. Teflon is known for self-lubricating and anti-corrosive property. To replace the conventional lubricating liquids such as oils. It was better to blend with two green ionic liquids prepared with alkyl amine and carboxylic acids produce the long molecular chains, feasible for a robust superlubricity under high contact pressure. Example to demonstrate such interested property is Teflon metal surface. Basically tribio chemical film were produced with very thin dense layer for super lubrication property. Carbon allotropes and carbon nano structures were highly crucial to achieve the superlubricity. Graphene layers, graphene ribbons, carbon nanotubes, ultra nano crystalline diamonds, carbon onion, fullerene deployed for the superflow friction properties. The percolation of thermal flux during two surface contact-friction process was achieved with the nano carbon structures. Rational design for the dimensional scaled nano materials follows the aspect ratio criteria more important parameter to achieve the superlubricnat surface properties too. However, the coating of bulk or surface by carbon allotropes nano structures act as tribochemical medium for achievement of super lubricant property of polymer surfaces. It is worthwhile for entire polymer surface energy applications. Nanoelectromechanical properties were optimised by using the concept of superlubricity.

www.ictmumbai.edu.in

#modernplasticsindia #plasticmagazine #indianmagazine #indianplasticmagazine #modernplasticsaward #ginujoseph #modernplastic #plasticindia #plasticnews #plasticrecycling #modernplasticsglobalnetwork #modernglobalnetwok #modernplasticsaward2022 #PlasticIndustry