World’s First Pilot Plant for Bio-Based Aniline

- Significant step toward producing plastics based on plant biomass.

- New process for petroleum-free raw material on its way to industrial maturity.

- Another milestone in the promotion of the Circular Economy accomplished.

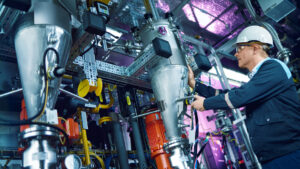

Covestro is moving forward with the implementation of a unique process for producing the important chemical aniline entirely based on plant biomass instead of petroleum for the first time. At its Leverkusen site, the plastics manufacturer has now put a special pilot plant into operation for this purpose. Initially, large quantities of bio-based aniline will be produced there, so that the new technology can be further developed for production and transferred to an industrial scale. In the plastics industry, aniline is used to produce MDI, among other things. This in turn is used for insulating foam, for example, which saves energy in buildings and reduces the CO2 footprint. Covestro believes it will contribute to the promotion of the Circular Economy, which the company is aiming to become fully aligned with.

In attendance at the opening ceremony were North-Rhine Westphalia’s Deputy Minister President Mona Neubaur as well as Professor Walter Leitner, Managing Director of the Max Planck Institute for Chemical Energy Conversion in Mülheim an der Ruhr. Together with Dr. Thorsten Dreier, Chief Technology Officer of Covestro, they discussed the significance of bio-based raw materials for a sustainable chemicals industry of the future.

“Among other things, aniline is a key raw material for foams used to insulate buildings and refrigerators,” explained Dreier, on the significance of the base chemical. “Until now, aniline has been produced from fossil raw materials such as petroleum, which releases CO2 and fuels climate change. With our new process, we are contributing to building up a circular, bio-based economy, and I am very proud that we have now succeeded in making the jump to the next technological level.”

Covestro developed the process, which has already won several awards, together with partners in the scientific community. Compared to conventional technology, the process leads to a greatly improved CO2 footprint of aniline. Covestro has made a seven-digit investment in the pilot plant at the Chempark Leverkusen.

“Sustainable innovations from North Rhine-Westphalia are making a decisive contribution to the transformation of Germany as a chemical location. The world’s first pilot plant for bio-based aniline is an impressive example of this,” emphasized Neubaur, who is also the State Minister for Economic Affairs, Industry, Climate Protection and Energy. “In order for the industry to continue on its path towards a circular economy and climate neutrality, it needs planning and investment security above all. As the state government, we are therefore working hard to ensure that North Rhine-Westphalia remains an attractive business location and becomes the first climate-neutral industrial region in Europe.”

Professor Leitner also underlined the importance of partnerships. “The project illustrates the cooperation between research-based industry and application-oriented science. There are many intersecting partnerships like these, especially in NRW. Germany needs more of this in order to assert itself as a research and technology location.”

Use of biotechnology

The project also clearly showcases the potential contribution of the industrial (“white”) biotechnology to plastics production: in the new process, a customized microorganism helps convert an industrial sugar extracted from plants into an intermediate product through fermentation. This takes place under milder and thus more environmentally compatible conditions than in conventional processes. In a second step, chemical catalysis of the intermediate product then creates the aniline with one hundred percent plant-based carbon.

The research on bio-based aniline will also continue to be funded by the German government. The German Ministry for Food and Agriculture is funding a follow-up project (Bio4PURDemo) from Covestro and partners, which started in March 2022 and runs until 2025.

The RWTH Aachen with the CAT Catalytic Center and the University of Stuttgart, as well as the technology transfer initiative located there, are also participating in the project.

Around six million tons of aniline are currently produced worldwide, with the volume growing by approximately three to five percent per year on average. With a production capacity of more than one million tons per year, Covestro is one of the leading aniline producers.

Minister for Economic Affairs, Industry, Climate Protection and Energy of the State of North Rhine-Westphalia and Deputy Prime Minister

Mona Neubaur, born in Pöttmes in 1977, came to North Rhine-Westphalia from Bavaria in 1997 and quickly made herself at home in the Rhineland. After graduating with a degree in education in 2003, she first worked in the energy industry and then at the Heinrich Böll Foundation NRW, including four years as Managing Director.

From 2014 to 2022, she was state chairwoman of the Greens in North Rhine-Westphalia. In December 2021, Mona Neubaur was elected top candidate for the 2022 state elections. She has been a member of the North Rhine-Westphalian state parliament since May 15, 2022. On June 29, 2022, she was sworn in as Minister for Economic Affairs, Industry, Climate Protection and Energy. At the same time, she was appointed by Minister President Hendrik Wüst as his deputy.

Managing Director Molecular Catalysis, Max Planck Institute for Chemical Energy Conversion

Walter Leitner is Director at the Max Planck Institute for Chemical Energy Conversion in Mülheim/Ruhr and Professor of Technical Chemistry and Petrochemistry at RWTH Aachen University. He is one of the initiators of the Catalysis Center CAT, a joint research facility of RWTH Aachen University and Covestro.

His research interests include catalysis, from its molecular foundations to reaction engineering concepts, in the context of “green chemistry”. The main focus of his scientific work is the development of novel catalysts and processes for the storage and use of renewable energy in the form of chemical energy carriers and products. His team’s basic research aims to use the “decarbonization” of energy generation to “defossilize” the chemical value chain.

Walter Leitner is the author and co-author of more than 400 scientific publications. He is co-speaker of the Cluster of Excellence “The Fuel Science Center” at RWTH Aachen University and of the BMBF-funded Kopernikus project “Power-to-X”. Together with Dr. Christoph Gürtler, Covestro AG, he was among the three finalists for the European Inventor Award (2021) and the Deutscher Zukunftspreis (2019) for his research on the use of CO2 as a raw material.

Chief Technology Officer and Labor Director Covestro AG

Dr. Thorsten Dreier has been a member of Covestro’s Board of Management as Chief Technology Officer (CTO) since July 2023 and the company’s Labor Director since September 2023. As the company’s Chief Technology Officer, he is responsible for the central functions Process Technology, Engineering, Group Health, Safety & Environment (Group HSE) and Group Procurement. He also coordinates the introduction of and compliance with global processes, standards and initiatives in Covestro’s production network.

Born in Münster in 1972, he studied chemistry and received his doctorate from the University of Münster in 2001. He began his career in 2002 as a laboratory manager in the Bayer Group and subsequently held various management positions at Bayer, Bayer Material Science and Bayer Technology Services. With the spin-off of Covestro, Dreier became Global Head of Production & Technology in the Coatings, Adhesives & Specialties business unit and later Global Head of the Specialty Films and Thermoplastic Polyurethanes businesses. Prior to his role on the Board of Management, he was Head of the Coatings & Adhesives business unit.

#modernplasticsindia #indianplasticmagazine #modernplasticsaward #plasticnews #modernplasticsgermany #ginujoseph #modernplastic #plasticindia #plasticrecycling #sustainability #modernplasticsglobalnetwork #modernglobalnetwork #modernplasticsaward2023 #plasticmagazine #PlasticIndustry #modernplasticsmiddleeast #indianmagazine #innovations #modernplasticsamerica #modernplasticsbangladesh #modernplasticsasia #modernplasticsitaly